Solar Powered Lighting Tower

Consumer electronics

2026

The Development

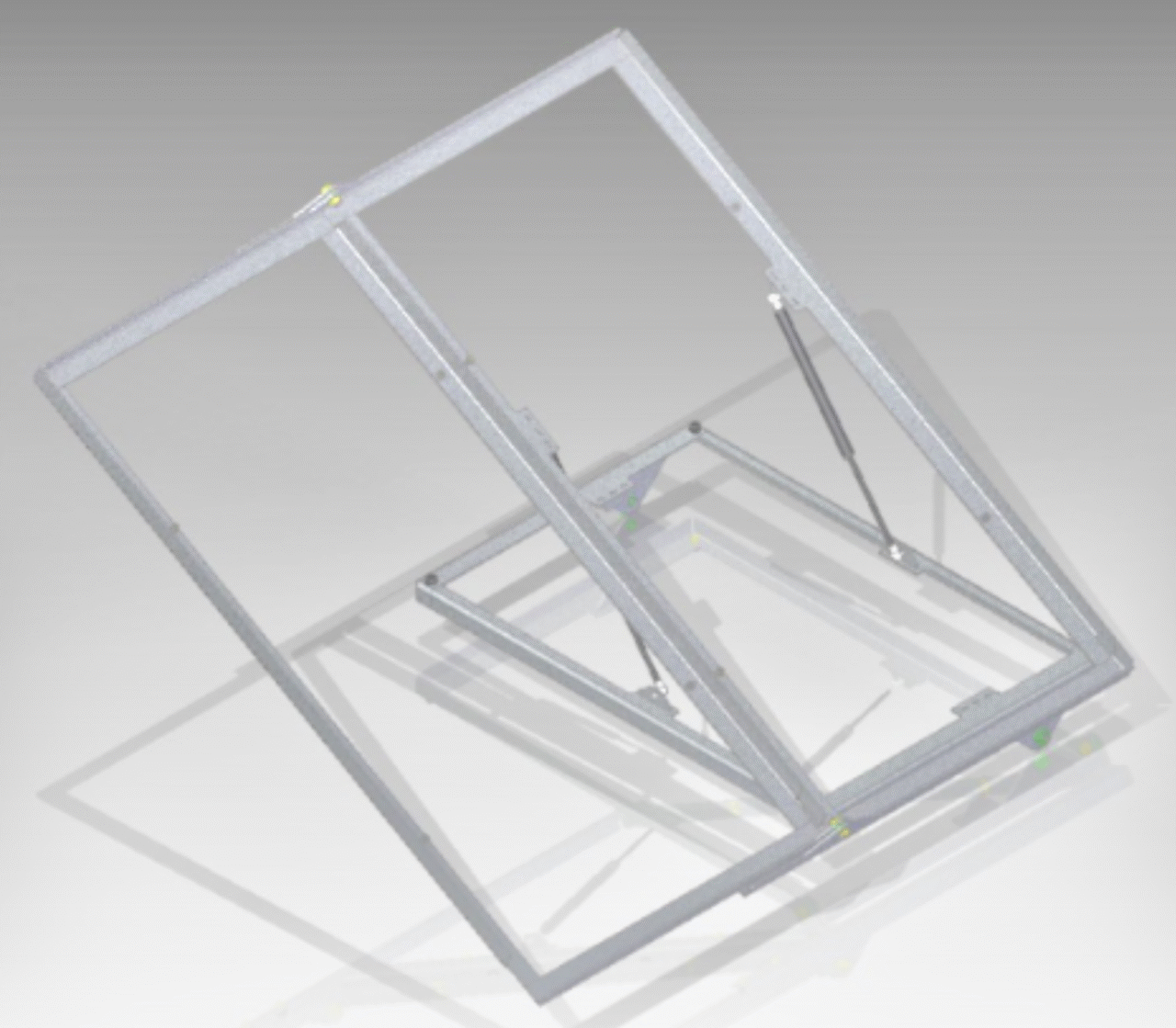

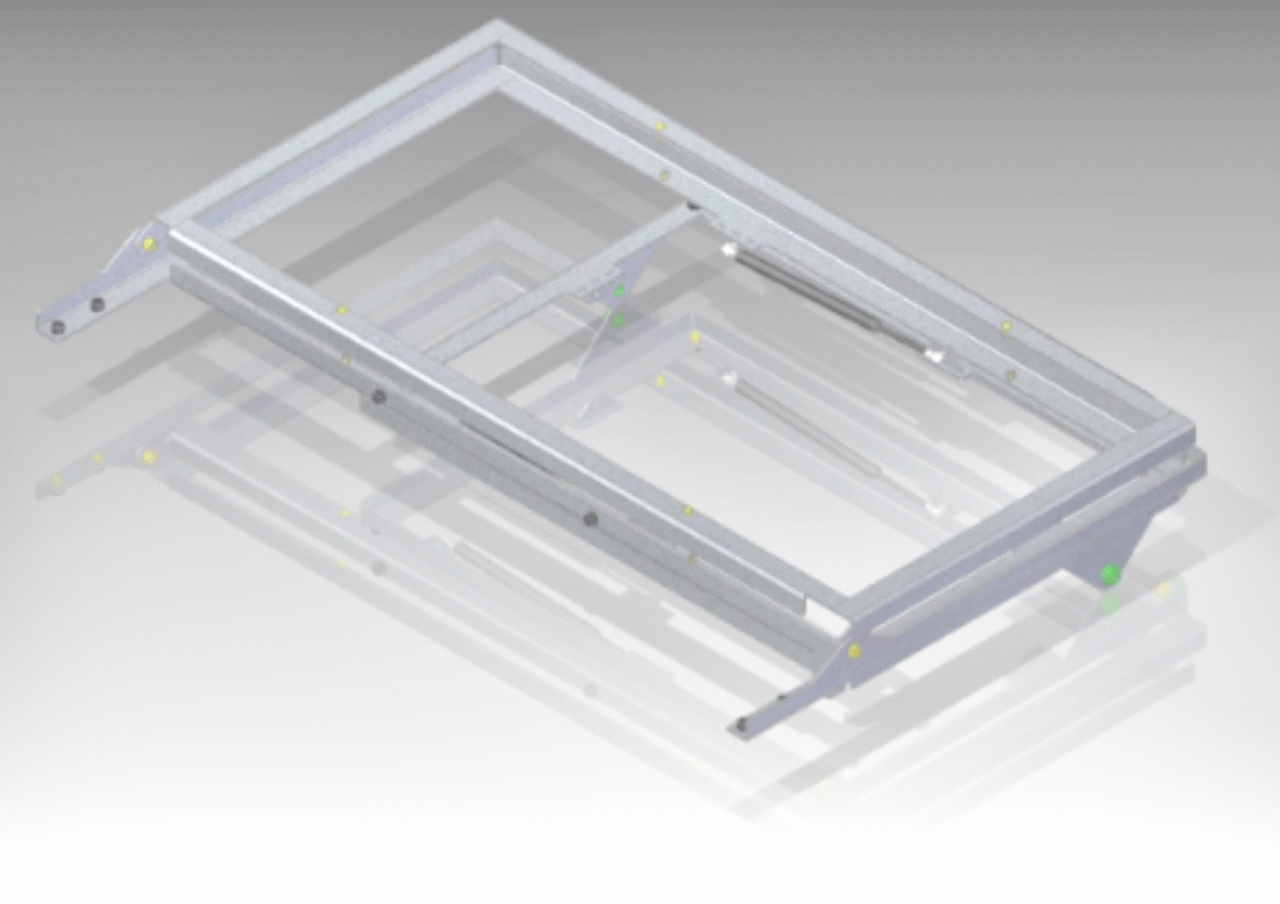

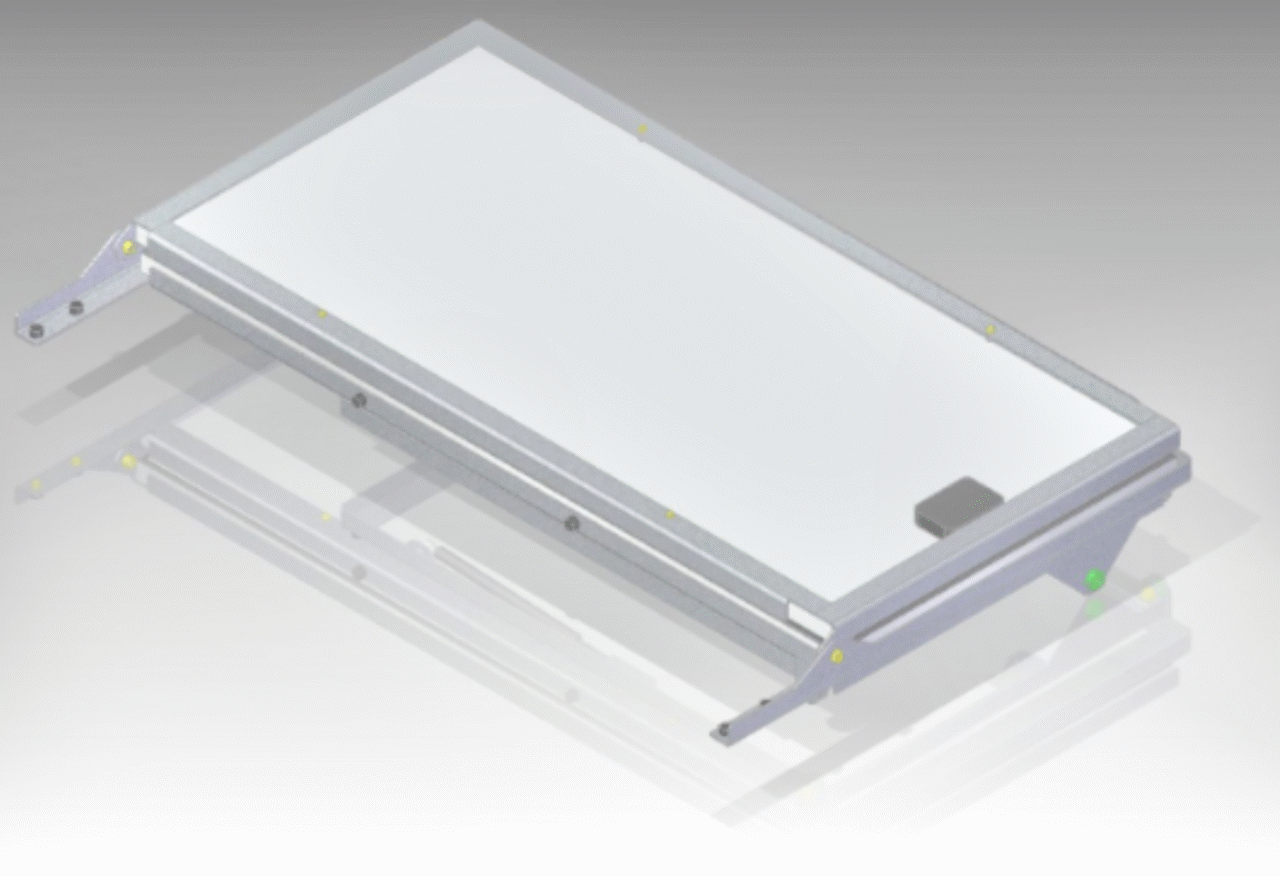

CAD modelling of the frames to check fit and function.

1st and 2nd Phase prototyping with the Development Engineer.

Targets throughout the design process were:

- Weight saving – The finished assembly should be able to be developed by one person.

- Safety during deployment and operation – The machine will be subject to wind and rain and had to employ locking mechanisms to ensure it would stay deployed whilst still manoeuvrable by one person.

- Safety during transport – The machine is likely to be towed and locking mechanisms had to achieve the same outcome as above.

- Servicing – All parts had to be designed for ease of service and interchanging parts.

- Adjustable – The frames had to be adjustable to achieve maximum efficiency during changing months and geographical location.

The Challenge

Solar Panels were required to be installed permanently onto the Light Tower Unit. Must be able to be folded away for transportation and held at an optimum angle. ‘Green’ was the theme for a trade show for Morris Site Machinery. The brief was to have a working prototype ready for the launch at a trade show.

Our Solution

The deadline was met with the SP-55 Lighting Tower being transported via tow. Fully working and branded for the show, the Lighting Tower is still on sale.

Gallery